was pretty easy. Nonetheless, it is worth putting the stage information in

a format that can make comparisons easier with other similar launchers.

However, it looks like we can safely say that the Vanguard is the second

smallest land-based launcher (by mass).

In summary, the Vanguard was a small three stage rocket launcher able to

place 22 lbs payloads into orbit. The first stage used liquid oxygen (LOX)

with kerosene as the fuel. The second stage used nitric acid with UDMH

as the fuel. The third stage was a solid rocket motor without guidance.

The second stage was responsible for orienting the third stage prior to

its ignition to ensure a proper orbit. As the Engineering Summary document

states:

"A three stage vehicle, with two guided stages and an

unguided but spin-stabilized third stage, fired at

second stage apogee, represented the most efficient

vehicle combination consistent with rocket technology

at that time."

One of the most obvious things about the Vanguard versus a solid launcherlike the Lambda 4S is that it has substantially lower mass ratios. Even

though the Vanguard is only a 3 stage vehicle, doesn't have substantially

higher Isp, it outperforms the Lambda 4S in delta V despite a larger effective payload.

THE STATISTICS

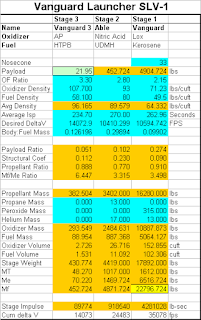

Here's the statistics table for Vanguard SLV-1. The SLV-1 was preceded by

six test vehicles, TV-0 through TV-5, and was the first operational version

of the design series. Later versions had numerous improvements over this

basic design. Although SLV-1 failed to place a payload in orbit, it represents

the basic Vanguard design and is the one that I used for my analysis. The

reason for SLV-1's failure likely was a control system problem which resulted

in stage 3 having an improper trajectory.

It should be pointed out that the calculated Gross Liftoff Weight (GLOW) is

different than that in the Engineering Summary document. This is because

they use a weight which includes ice on the Lox tank and aerodynamic

surfaces used on the ground to minimize wind shaking of the vehicle.

Therefore, the GLOW used in the analysis subtracts out the ice and

aerodynamic wind breaks.

One other significant issue is that the nosecone is properly part of stage 2

but its weight is included in stage 1. The reason for this is that the nose cone

is ejected from stage 2 shortly after separation and therefore, its effects

are not felt by stage 2 but mostly by stage 1.

STAGE 1

Although the Engineering Summary document is authoritative, making sense

of the effects of various weights on stage 1 requires careful attribution

of various weights to the overall stage performance. In the Rocket Equation,

it is important to get the weight at liftoff (GLOW) and the weight at stage

burn out correct as well as the effective specific impulse (Isp). These weights

have to be factored properly into the analysis or the results will not be

as accurate as one might desire.

In the case of stage 1, it is necessary to figure in the weights of the

Hydrogen Peroxide and the Helium used in the propulsion system and account

for their effect on both the weight and the effective propulsion system

efficiency as expressed by the average Isp. This means that the weights

of these fluids must be included into the weight of the "propellants"

which includes the oxidizer and the fuel. Doing so, gives the stage

weights below:

Fuel and Oxidizer: 15952 lbs Helium: 13 lbs Hydrogen Peroxide: 315 lbs --------------------------------- Propellant Weight: 16280 lbsIt should be noted that the total Hydrogen Peroxide weight was given

as 340 lbs, but only 315 lbs is reported as having been used. Therefore,

the additional 25 lbs was assigned to the burnout weight of stage 1.

Reported Emtpy Wt: 1587 lbs Unused Peroxide: 25 lbs --------------------------------- Burnout Weight: 1612 lbsThe first stage engine used a turbopump to raise the propellant feed pressure

to 616 PSI. The exhaust gas of the turbopump was directed to roll control

nozzles to provide attitude control beyond the stage 1 motor gimballing.

STAGE 2

Stage 2 used pressure fed nitric acid and Unsymmetrical DiMethyl Hydrazine (UDMH)

as propellants. The motor used was an Aerojet AJ10-37. The AJ10 motor, with

improvements, has continued to be used to this day in the Delta II upper stage.

With variations, this motor has also been used on the Apollo Service Module and

on the Shuttle's Orbital Maneuvering System. This motor has a long history from

the first American orbital attempts to this day.

One surprising aspect of stage 2 is its use of liquified propane as the attitude

control gas for roll control. A blanket heater was used to keep the propane

vapor pressure at 240 PSI. Again, the propane's weight has to be taken into

account for the stage performance

Fuel and Oxidizer: 3372 lbs Propane: 13 lbs Helium: 17 lbs -------------------------------- Propellant Weight: 3402 lbsSTAGE 3

Stage three used a solid rocket motor which was spun along its axis to

maintain orientation. The second stage essentially used "point and

shoot" with the third stage and it contained the guidance system.

A spring-loaded separation device separated the payload from the third

stage motor at the appropriate time.

PERFORMANCE SUMMARY

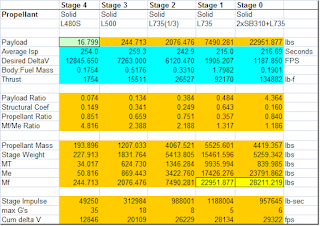

Based on the vehicle defined in the performance table, above, an

aerodynamic model and an Isp vs altitude model, a simulation was

performed to identify various performance characteristics. The

trajectory was made to match the published values in the Engineering

Summary. From this, we can estimate gravity and aerodynamic losses

of the first stage.

Designed delta V: 10594.742 fps Observed delta V: 6399.13 fps Aerodynamic Losses: 440.31 fps Gravity Loss: 3755.302 fpsAdditionally, we can observe the apparent allocation of delta velocity (delta V)

to each stage:

Stage 3: 14072.890 fps Stage 2: 10410.299 fps Stage 1: 10594.742 fps ------------------------------------- Total: 35077.931 fpsSUMMARY

The Vanguard satellite launcher provides an interesting example for those

interested in small launch vehicles. The idea of a small launch vehicle

with an unguided final stage provides one way to simplify the design

and development task. It drops the weight of the guidance system from

the final stage where it will have the greatest impact on launch vehicle

weight, down to the second stage where it will have less effect.

The Vanguard satellite launch vehicle is a fascinating example of a

small orbital launcher.

REFERENCE

The Vanguard Satellite Launching Vehicle - An Engineering Summary

http://hdl.handle.net/2060/19740072500